Top Fly Ash Brick Making Machines in India

The construction industry in India has been experiencing rapid growth, and with it comes an increased demand for sustainable building materials. Fly ash bricks have emerged as an eco-friendly alternative to traditional clay bricks, offering superior strength and durability. As a result, the market for fly ash brick making machine in India has expanded significantly. In this comprehensive guide, we'll explore the top fly ash brick making machines available in India, their features, and the benefits they offer to manufacturers and the environment.

Why Choose Fly Ash Bricks?

Before delving into the machines that produce these innovative bricks, let's understand why fly ash bricks have gained such popularity:

1. Environmental Benefits: Fly ash bricks utilize industrial waste, reducing the environmental impact of coal-fired power plants.

2. Energy Efficiency: The production process requires less energy compared to traditional clay bricks.

3. Cost-Effective: Lower production costs translate to more affordable building materials.

4. Strength and Durability: Fly ash bricks offer superior compressive strength and weather resistance.

Top Fly Ash Brick Making Machines in India

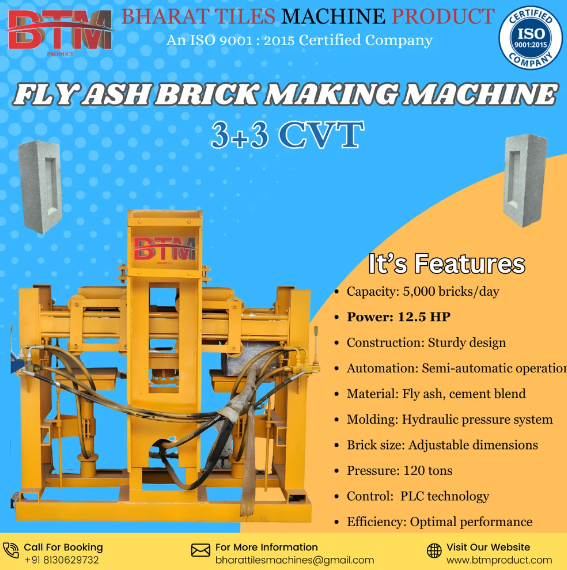

1. BTM Product's Fully Automatic Fly Ash Brick Making Machine

BTM Product, a leading manufacturer in the industry, offers a state-of-the-art fully automatic fly ash brick making machine in India. This high-capacity machine is designed for large-scale production and boasts the following features:

- Production Capacity: Up to 20,000 bricks per day

- Hydraulic System: Ensures consistent pressure and brick quality

- PLC Control: Automated operations for improved efficiency

- Customizable Molds: Produces various brick sizes and shapes

2. Semi-Automatic Fly Ash Brick Making Machine

For medium-scale manufacturers, semi-automatic machines offer a balance between production capacity and investment. Key features include:

- Production Capacity: 8,000 to 12,000 bricks per day

- Manual Feeding: Allows for quality control of raw materials

- Hydraulic Pressure: Ensures uniform brick density

- Low Maintenance: Simplified design for easy upkeep

3. Manual Fly Ash Brick Making Machine

Small businesses and startups may opt for manual machines, which offer:

- Production Capacity: 2,000 to 5,000 bricks per day

- Low Initial Investment: Ideal for those entering the market

- Versatility: Can produce various brick types with mold changes

- Portability: Easy to relocate for on-site production

Interlocking Tiles and Paver Blocks: Diversifying Your Product Line

While fly ash bricks are the primary focus, many manufacturers are expanding their product offerings to include interlocking tiles making machine in India and paver block making machine in India. Let's explore the machines that can help diversify your production:

Interlocking Tiles Making Machine in India

Interlocking tiles have gained popularity for their aesthetic appeal and ease of installation. BTM Product offers versatile machines that can produce both fly ash bricks and interlocking tiles:

- Multi-Function Capability: Switch between brick and tile production

- Various Patterns: Create a range of interlocking designs

- Color Mixing Option: Produce vibrant, customized tiles

- High Precision: Ensure consistent tile thickness and strength

Paver Block Making Machine in India

Paver blocks are essential for landscaping and outdoor flooring applications. The paver block making machine in India offered by BTM Product boasts:

- Vibration Technology: Ensures uniform density and strength

- Multiple Mold Options: Produce various shapes and sizes

- Color Mixing System: Create attractive, multi-colored pavers

- High Production Rate: Meet growing market demand efficiently

Factors to Consider When Choosing a Fly Ash Brick Making Machine

1. Production Capacity

Assess your current and future production needs to select a machine that can scale with your business.

2. Automation Level

Consider your workforce and production goals when deciding between manual, semi-automatic, or fully automatic machines.

3. Quality Control Features

Look for machines with features like pressure adjustment and uniform material distribution for consistent brick quality.

4. Versatility

Opt for machines that can produce various brick sizes and potentially other products like interlocking tiles or paver blocks.

5. After-Sales Support

Choose manufacturers like BTM Product that offer comprehensive training, maintenance, and spare parts availability.

6. Energy Efficiency

Consider machines with energy-saving features to reduce operational costs and environmental impact.

Maximizing Efficiency in Fly Ash Brick Production

To get the most out of your fly ash brick making machine in India, consider these tips:

1. Raw Material Quality: Use high-quality fly ash and other ingredients for superior brick strength.

2. Proper Mixing: Ensure thorough mixing of raw materials for consistent brick composition.

3. Regular Maintenance: Follow the manufacturer's guidelines for machine upkeep to prevent breakdowns.

4. Staff Training: Invest in proper training for operators to maximize machine efficiency and product quality.

5. Quality Control: Implement rigorous testing procedures to maintain brick standards.

The Future of Fly Ash Brick Manufacturing in India

As the construction industry continues to prioritize sustainable building materials, the demand for fly ash bricks is expected to grow. Manufacturers who invest in efficient, high-quality fly ash brick making machine in India will be well-positioned to capitalize on this trend.

BTM Product remains at the forefront of this industry, continuously innovating their machines to meet evolving market needs. Their commitment to quality and customer support makes them a trusted choice for businesses entering or expanding in the fly ash brick manufacturing sector.

Conclusion

The fly ash brick making machine industry in India is experiencing significant growth, driven by the increasing demand for sustainable construction materials. From fully automatic high-capacity machines to versatile equipment that can produce interlocking tiles making machine in India and paver block making machine in India, manufacturers have a wide range of options to choose from.

BTM Product stands out as a leading provider of fly ash brick making machines in India, offering a comprehensive range of equipment suitable for businesses of all sizes. Their machines not only produce high-quality fly ash bricks but also provide the flexibility to diversify into interlocking tiles making machine in India and paver blocks, allowing manufacturers to meet various market demands.

As you consider entering or expanding your presence in the fly ash brick manufacturing industry, carefully evaluate your production needs, budget, and growth plans. Investing in the right fly ash brick making machine can set the foundation for a successful and sustainable business in India's evolving construction materials market.

Remember, the key to success lies not just in choosing the right machine but also in maintaining high product quality, efficient operations, and a commitment to sustainability. With the right equipment and approach, you can contribute to India's green construction movement while building a profitable and impactful business.

Comments

Post a Comment